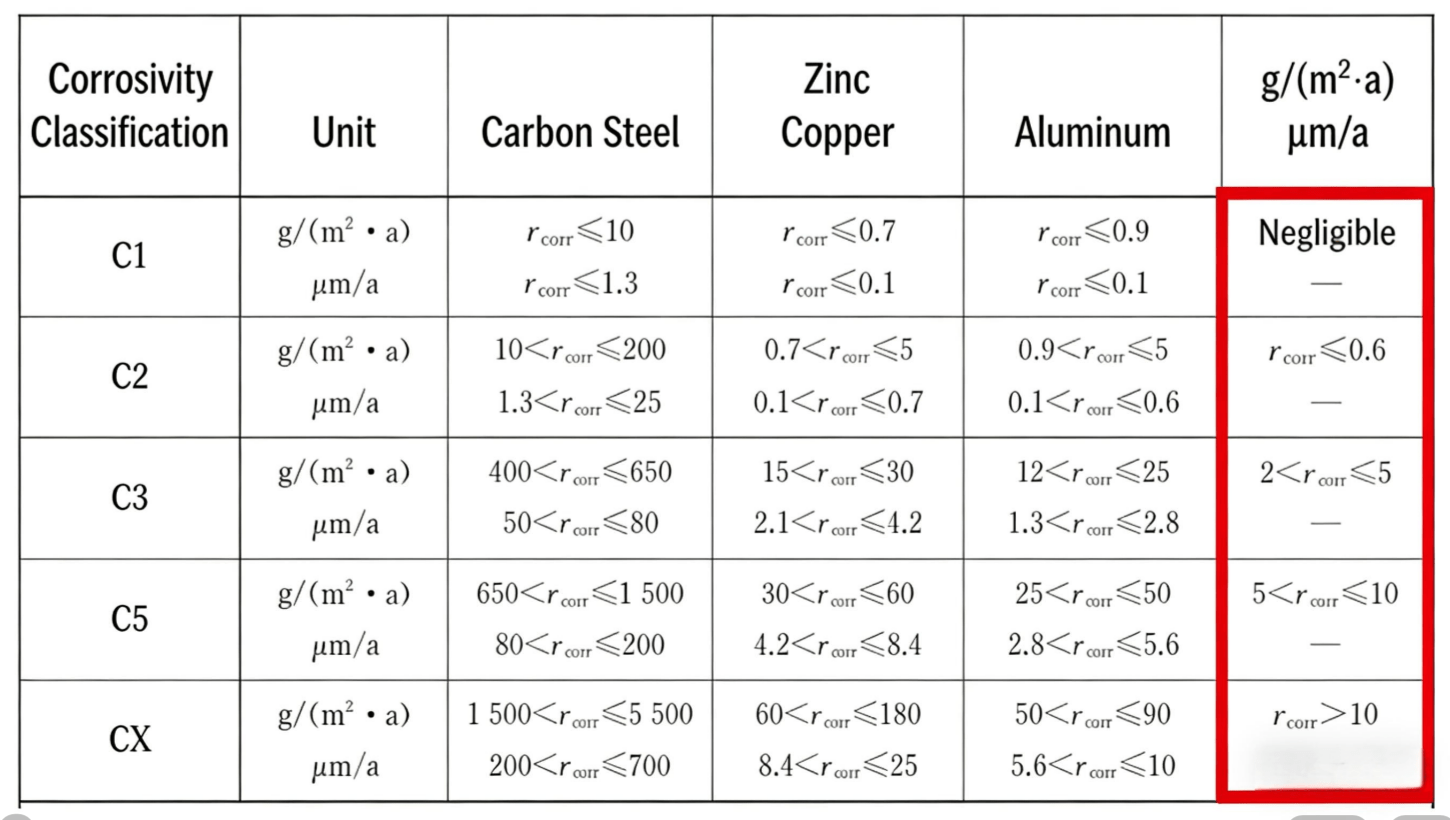

C1 Class (Slightly Corrosive Environment)

Corrosion of aluminum alloys is negligible, far superior to metals such as carbon steel, zinc, and copper.

C4 Class (Moderate to Severe Corrosion Environment)

The corrosion rate of carbon steel is 130 to 200 times that of aluminum, while pure zinc is 6 to 7.5 times that of aluminum.

C5 Class (Severe Corrosion Environment)

The corrosion rate of carbon steel is 130 to 200 times that of aluminum, while pure zinc corrodes at a rate 6 times that of aluminum.